Equipment and techniques for measuring L, Q, SRF, and DCR |

Introduction |

Accurately measuring inductance is always more difficult than measuring other passive components. The main difficulty in measuring coils is that the inductance and efficiency of the coil are largely affected by frequency; Similarly, the parasitic effects of coils (distributed capacitance and iron core/copper wire resistance losses) will undergo significant changes with frequency. Measuring coils at the applied frequency, also known as' frequency testing ', is more representative of the base values of components in a circuit than testing at traditional standard frequencies. Usually, the measurement frequency is only specified for the convenience of measurement. If the measured frequency is not the frequency of the circuit (or "use"), the test results generally cannot achieve the same inductance value or demonstrate the same efficiency as the specified circuit. Given the recent developments in equipment and methods, and the flexibility to choose testing frequencies, inductors should be tested at actual usage frequencies, especially when high precision is required. |

Inductance parameters |

The main electrical parameters of a coil are inductance, Q (efficiency), DC resistance (DCR), and self harmonic frequency (SRF). All major electrical parameters are controlled by the design, although not entirely. Inductance and Q are often greatly influenced by the testing instruments and frequency used. Q reflects the efficiency of inductance, which is the ratio of stored energy to dissipated energy of the component. Q reflects the energy storage capacity of an inductor, which is directly proportional to the measurement frequency and inversely proportional to the resistance (copper wire and iron core) loss generated by the component at the same frequency. DCR is the resistance of copper wires in an inductor to current when a constant DC current is applied. DCR allows us to understand the insertion loss that occurs in a circuit due to the addition of inductance. DCR also indicates how much energy the inductor will consume only when it generates heat. When the frequency exceeds SRF, the function of the component is no longer inductance. SRF is determined by the parallel combination of (low-frequency) inductance and the effective capacitance between turns of the coil. |

Test equipment |

The appropriate selection of testing methods largely determines the accuracy of measurements. The testing instruments and methods used for different electrical parameters are different, and each instrument has a range, frequency, and error limit. Parasitic effects and the influence of testing fixtures are factors that cannot be ignored in measurement. In general, instruments, fixtures, frequencies, and currents (if applicable) must be specified to achieve repeatable and reliable testing. Impedance analyzers are generally used to measure the inductance and Q of inductive components. Network analyzers have also been widely used to measure Q. The zero phase method can be used to measure SRF on network analyzers. DCR is usually measured using a low resistance meter. The choice of tester also affects the measured values. The impact of instruments is caused by the use of different measurement methods and frequencies for each device. Some of the differences can be attributed to different instruments, but mainly due to different frequencies. In short, the correct instrument should be one that can perform accurate and repeatable testing at the required frequency. Agilent/HP 4991A and 4287A are commonly used to measure the inductance of RF coils. The frequency range of these impedance analyzers is 1 MHz to 3 GHz, which can meet the measurement requirements at practical application frequencies. |

Traditional methods for measuring inductance |

For decades, the Q-table has been the traditional method for determining the values of L and Q parameters. However, the Q table requires the test frequency to be within the range of its oscillator and the limits of the tuning capacitor. Meanwhile, the inductance measured by the Q-meter is expressed in terms of capacitance (pF). The Q meter also has a specific frequency (called the blue line) that is easier to use than the intermediate frequency, because the additional dial on the tuning capacitor can directly read the inductance. The accuracy of Q meters available on the market is 3% or even lower. The Q-table error requires the use of a set "standard component" (determined as a high-precision component with specific and precise values). Calibration parts are like standards with specific values determined by suppliers and users. Calibration components are considered as specific standard components and are used to set up each instrument during each test. Calibration remains the most accurate method, with small errors, high repeatability, and applicability at any frequency. However, the calibration method has serious logistical deficiencies: the development and measurement of calibration parts between manufacturers and customers, as well as the work of testing and debugging instruments every time. Other electrical parameters SRF and DCR are generally specified based on L and Q, but there is little explanation of the testing methods used for them. The lack of specific testing methods for SRF and DCR indicates that inductance is the main parameter and requires careful control. |

Application frequency testing |

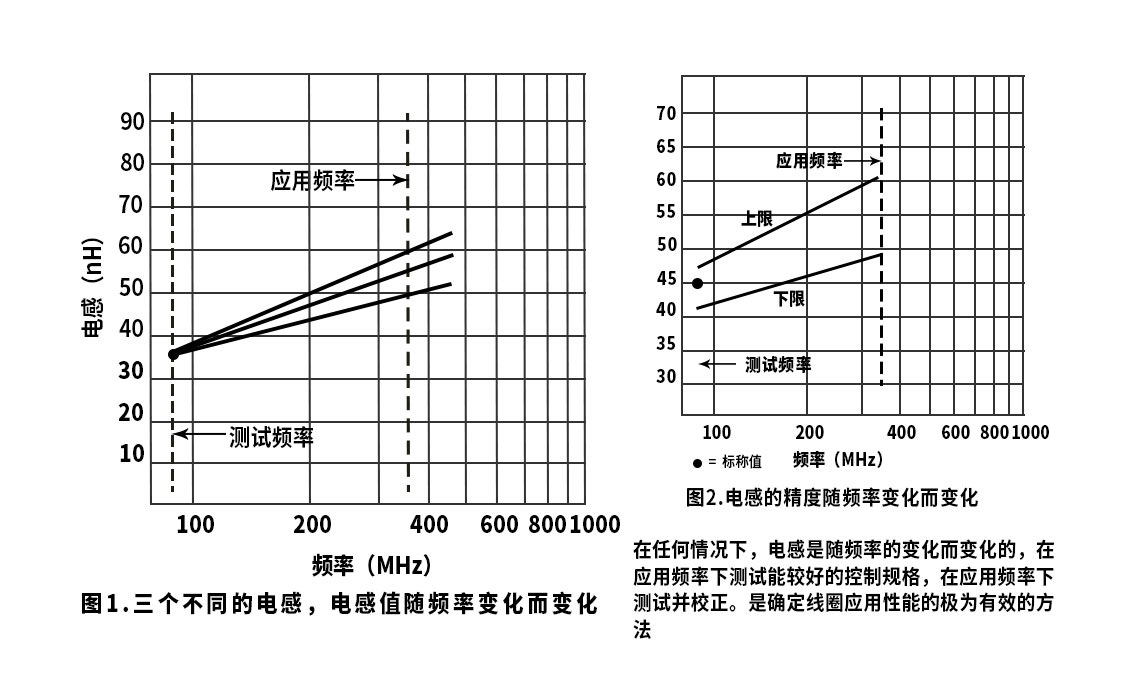

The basic difficulty of traditional testing methods is that the coil is tested at one frequency and used at another frequency. Figures 1 and 2 illustrate the fundamental issues of traditional testing methods. |

|

Inductance and Frequency |

Figure 1 shows logarithmic scans of inductance values and frequencies for three different inductors. When these products are tested at a standard frequency, their inductance values appear to be the same. At actual circuit frequencies, these coils are quite different. These three coils can represent three different designs or three different coils of the same design. If the frequency is used at the point where three inductors converge, then these coils are equivalent. If the circuit frequency is significantly different from the test frequency, then the inductance at the test frequency generally cannot represent the inductance at the operating frequency. Even if these coils do not deviate from each other, the inductance value will still change. When a design requires a specific inductance value and a particular coil fails to achieve the expected value, the result of the inductance changing with frequency is reflected. This change is usually caused by differences in fixtures and circuit parasitic effects, resulting in specific values being correspondingly offset. Figure 2 shows another result of testing at both testing frequency and application frequency. It displays the variation of inductance accuracy of a specific coil with frequency. The nominal inductance values and their tolerances at both frequencies are displayed. If the tolerance of the coil at the test frequency is 5%, then the tolerance at the application frequency may be 10%. These tolerance limits decrease or increase with frequency, depending on the design of the coil. The fact that the tolerance limit is not constant leads to the loss of control over accuracy as frequency changes. |

Determine the inductance test at the application frequency |

The electrical steps for testing an inductor at the frequency of use are as follows: |

Inductance |

1.Determine the nominal inductance value. 2. Determine the testing instruments, fixtures, and frequency. 3.Determine the inductance tolerance. a.Use Six Sigma or other suitable methods to determine the allowable percentage tolerance. b. Evaluate the instrument error of nominal impedance at the testing frequency. Subtract this percentage error from the allowable tolerance determined in step 3a. c.Determine the repeatability of instruments and fixtures. Subtract this percentage error from the result of step 3b. This result is within the specified tolerance. Since all errors have been taken into account, manufacturers should test according to the specified tolerances without the need for calibration. |

Q |

1. Determine the absolute minimum Q value (allowable minimum value). Use Six Sigma or other suitable methods to determine the allowable minimum value. Customers should conduct testing based on this tolerance. 2. Determine the testing instruments, fixtures, and frequency. 3. Determine the minimum Q value for manufacturing. a. Evaluate the instrument error of nominal impedance at the testing frequency. The minimum allowable value determined in calibration step 1 (i.e., adding the minimum Q value to a number equal to the instrument error). b. Determine the repeatability of instruments and fixtures. Adjust the new allowed minimum value determined in step 3a (i.e. add the minimum Q value to a number equal to the test repeatability). This result is within the specified tolerance. Since all errors have been incorporated into the final adjusted Q specification, the manufacturer should test according to the specified tolerances without calibration. |

DCR |

1. Determine the absolute maximum DCR (maximum allowable value). Use Six Sigma or other suitable methods to determine the maximum allowable value. 2. Determine the testing instruments and fixtures. 3. Determine the maximum DCR for manufacturing. a. Evaluate the instrument error of nominal resistance. Correct the maximum allowable value determined in step 1 (i.e. subtract the maximum DCR by a number equal to the instrument error). b. Determine the repeatability of instruments and fixtures. Adjust the new maximum allowable value determined in step 3a (i.e. subtract the maximum DCR by a number equal to the test repeatability). This result is within the specified tolerance. Since all errors have been incorporated into the final DCR specifications, the manufacturer should test according to the specified tolerances without calibration. |

SRF |

Determine the absolute minimum SRF (allowable minimum value). Assuming that there is a need for testing in the selected batch of devices, only the inductance value needs to be tested 100%. The other parameters are accompanied by the inductance value, so only verification is required. Due to different fixtures and environmental factors, using calibration methods and testing at the frequency of use can eliminate errors and tighten specifications. The calibration method can be used for any parameter of inductance, but is most commonly used for inductance and Q. |

Conclusion |

The coil inductance and Q are influenced by frequency, and the testing method has a further impact on these parameters. Determining and testing at actual circuit frequencies is an appropriate method for controlling inductance parameters. Frequency testing can ensure that components are consistent with their actual applications. The main parameters of inductance are interrelated coil design functions. Inductance specifications should take into account component variables and measurement system errors. |